Downloadable Wiring Diagram

Yes, you can add brakes to your 2000 lb trailer axle!

To get started, you’ll want to ensure you have the proper components. Check out our selection for Trailer Axle Drums here: 2000 lb Hub and Drums.

You’ll also need the correct braking system for your setup. For that, we offer a variety of Trailer Brakes specifically designed for 2000 lb trailers. You can explore these options here: 2000 lb Trailer Brakes.

Together, these components will help ensure that your trailer axle is properly equipped and safe for use. Happy towing!

Answer:

• Electric Brakes: These are common and effective for trailers in this weight range. They provide proportional braking power based on the trailer’s load.

• Hydraulic Brakes: Found on some heavy-duty trailers, they offer consistent braking performance but require a hydraulic brake controller.

• Considerations: The choice depends on your trailer’s usage, compatibility with your towing vehicle, and local regulations. Check your manufacturer’s guidelines to ensure you choose the right type and capacity.

Answer:

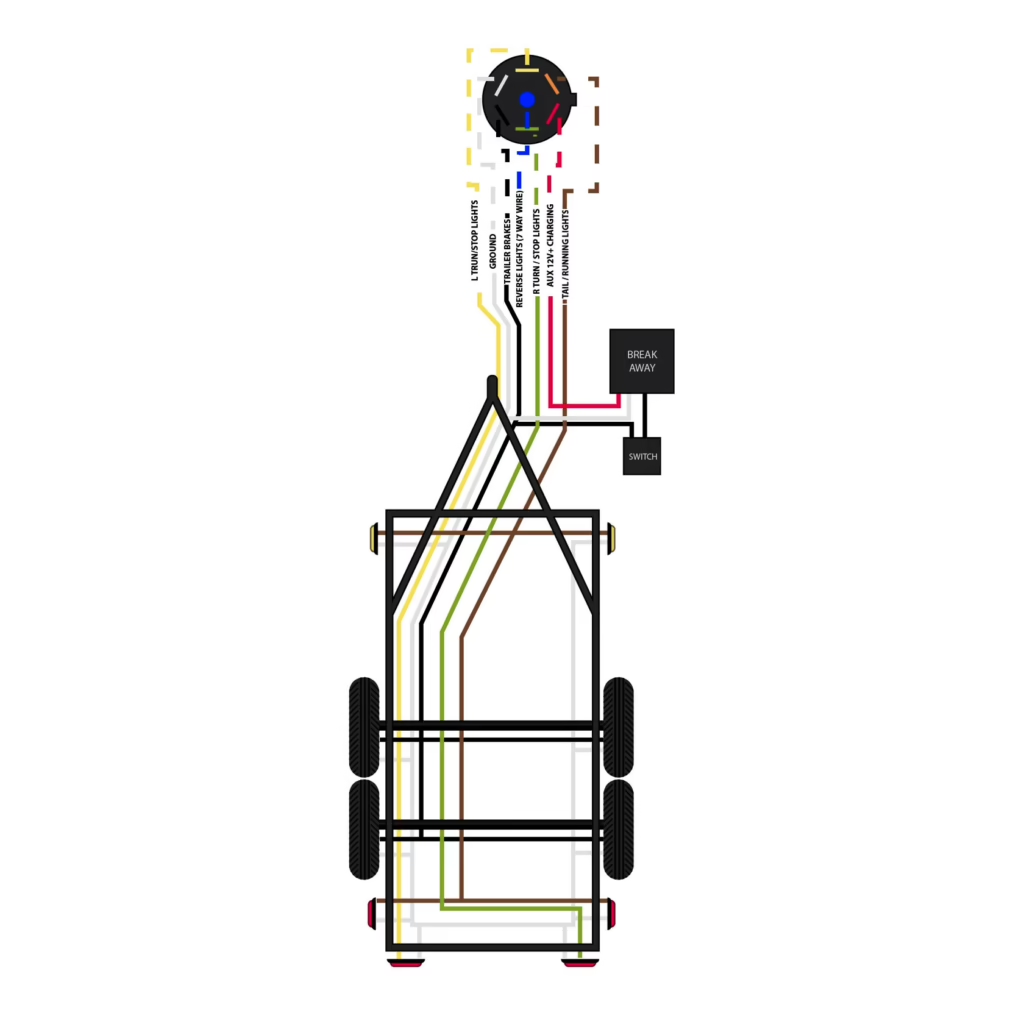

• Wiring Basics: Trailer brake wiring usually consists of a ground wire, a positive brake signal wire, and sometimes additional wires (such as for reverse lights).

• Secure Connections: Ensure connections are clean, corrosion-free, and secured with proper connectors (quick disconnects, spade connectors, etc.).

• Fuse Protection: Most systems include a fuse to protect against shorts.

• Reference Diagrams: Always consult the wiring diagram provided by your brake manufacturer, as wiring colors and configurations can differ between models.

• Testing: Once wired, test the trailer brakes with the vehicle stationary before hitting the road. If your brakes aren’t activating properly, recheck the connections and consult the manufacturer’s instructions.

Answer:

• Definition: Burnishing is the process of ‘seating in’ the brake shoes or pads by gradually building up friction material contact.

• Purpose: This helps ensure that the brakes engage smoothly and evenly over the entire surface, leading to improved performance and longer life.

• Process:

• Initial Break-In: Lightly apply the brakes at low speeds in a controlled environment to generate minimal, consistent heat.

• Multiple Cycles: Repeat braking gently several times to smooth out the contact surface.

• Consequences of Skipping Burnishing: Without proper burnishing, you might experience uneven braking, reduced effectiveness, or premature brake wear.

Answer:

• Preparation:

• Verify you have the correct brake system for your trailer’s weight.

• Gather all tools and refer to the installation manual.

• Mounting the Brakes:

• Securely mount the brake assemblies (whether they are drum or disc brakes) to the trailer axle.

• Check that all hardware is tightened to the manufacturer’s specifications.

• Wiring:

• Run the wiring through the designated channels and secure them away from moving parts.

• Connect the wiring according to the wiring diagram.

• Adjustments:

• Adjust the brake shoes or pads for proper contact with the drum or rotor.

• Ensure there’s proper clearance as recommended in the instructions.

• Testing:

• After installation, test the brakes in a safe, controlled environment.

• Make any necessary fine-tuning adjustments for optimal performance.

Answer:

• Double-Check Wiring: Improper connections or a bad ground can lead to non-functioning brakes.

• Review Adjustments: Ensure the brake shoes/pads are adjusted correctly. Uneven contact may cause dragging or poor braking performance.

• Inspect Burnishing: Inadequate burnishing can result in a delay or inconsistency in brake engagement.

• Consult Documentation: Refer back to your manufacturer’s installation and troubleshooting guides for specific diagnostic tips.

• Professional Help: If you continue to have issues, consult a trailer brake specialist or mechanic for an in-depth inspection.

Yes, we do! We take quality and safety very seriously. Unlike some competitors (like Dexter Brakes), if your brake pads ever show signs of cracking, we stand by our product with a lifetime no crack warranty. This means that if you ever notice any cracks in your brake pads, we’ll replace them free of charge. Our commitment is to provide reliable, safe braking performance throughout the life of your trailer.

Answer:

Troubleshooting trailer brake issues can involve a few key steps. Here’s a simple guide to help you diagnose common problems:

1. Check the Wiring and Connections:

• Inspect All Wiring: Look for loose, frayed, or corroded wires. Ensure that connections (including the ground) are secure and clean.

• Verify the Fuses/Relays: Check that your trailer’s fuse and any brake relay are functioning correctly.

• Consult the Wiring Diagram: Refer to your brake manufacturer’s wiring diagram to ensure that each connection is correct.

2. Examine Brake Components and Adjustments:

• Inspect Brake Pads/Shoes: Look for wear, glazing, or uneven wear. Remember that cracked pads can trigger warranty claims if applicable.

• Check Brake Adjustments: Make sure the brake shoes or pads have the correct amount of clearance with the drum or rotor. Too much clearance can lead to delayed braking, while too little can cause dragging.

• Confirm Burnishing Process: If your brakes are new, verify that they were properly burned in. Inadequate burnishing can lead to inconsistent engagement.

3. Test the Brake Controller and Signals:

• Functionality Check: Ensure that the brake controller in your tow vehicle is calibrated and functioning as it should.

• Signal Verification: Use a multimeter to check that the proper voltage is reaching the trailer brakes when activated.

4. Look for Overheating or Binding:

• Overheating Signs: If the brakes feel ‘grabby’ or if you notice a burning smell during operation, the brakes may be overheating.

• Check for Binding: Ensure that the brakes engage and disengage smoothly. Binding or dragging can indicate issues with the adjustment or mechanical components.

5. Review Installation Details:

• Proper Mounting: Confirm that the brake assemblies and hardware are securely installed. Loose mounting can affect performance.

• Clearance and Alignment: Double-check that the hub face, wheel, and brake drum/rotor are properly aligned.

6. Consult Documentation and Support:

• Owner’s Manual: Revisit the installation and troubleshooting sections in your owner’s manual.

• Professional Assistance: If you’ve run through these steps and are still experiencing problems, consider consulting a trailer brake specialist or a professional mechanic.

Upgrade your trailer’s braking system with the 3500 lb Trailer Electric Brake Axle Service Kit. Designed for 3,500 lb capacity axles, this kit combines high-quality self-adjusting brakes, pre-greased hub-and-drum assemblies, and all essential components for reliable towing performance. Engineered to fit most 5 on 5 bolt pattern axles, this comprehensive Axle Service Kit simplifies installation while maximizing safety and durability. Certified by both CSA and QAI, this kit meets rigorous standards for quality and reliability.

Order your 3500 lb Trailer Electric Brake Axle Service Kit – 5 on 5 today and enjoy free nationwide shipping. Don’t settle for less when it comes to the safety and performance of your trailer. Upgrade with confidence and experience the difference!

You must be logged in to post a review.

TowParts.com delivers top-quality trailer and RV parts with fast, reliable service and expert support. With fair prices, an easy shopping experience, and accurate information, we guarantee a hassle-free process from order to delivery.

• Customer-Centric Service

• Integrity & Transparency

• Quality Assurance

• Reliable Fulfillment

Reviews

There are no reviews yet.